Maintenance is crucial for generators that are used on a daily basis, but it’s just as important for a standby set.

After all, you don’t want to be sitting at work during a blackout with a backup generator that won’t start because you forgot to check its fluid levels. If you’re not sure where to start, give us a call at +1 832 948 6019 and hire our services for upkeep and tuning.

In the meanwhile, let’s take a deeper look at why you need to get regular maintenance work done on standby generators.

Creating a Backup Generator Maintenance Plan

If you’re not sure where to start, the manufacturer’s maintenance instruction manual is a pretty good first step. While a backup generator needs minimal maintenance, it’s still a good idea to create weekly and monthly checklists. Keep in mind that the environmental conditions of the area—humid, dry, dusty, or extremely hot—because they may create special requirements.

The basic maintenance plan will involve five steps:

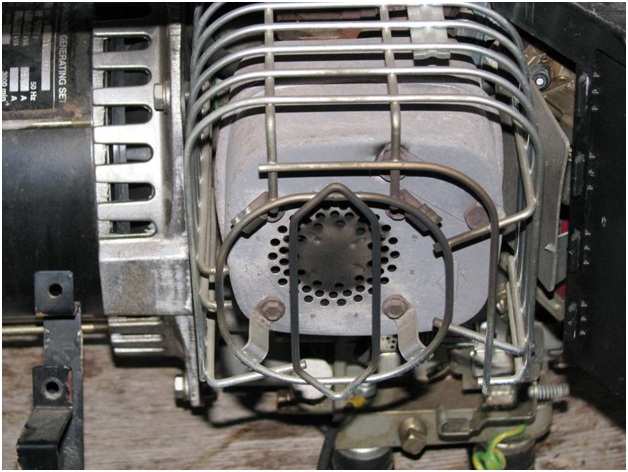

- You’ll need to run the generator at least once a week to make sure it’s functioning at optimal levels. Check for fluid and oil leaks that may be caused by loose components or faulty fixtures. If your backup generator is facing wear and tear, fluid leaks can occur due to a deteriorating gasket.

- On a monthly basis, perform fluid analysis and ensure that there are no irregularities in the engine. Modern generator sets are designed to automatically shut down when they detect a problem with engine or fluid levels. To avoid this from happening in the middle of a power outage, clean up debris and grime in the areas surrounding the engine and check the battery power.

- Biannually, perform battery checks; thoroughly inspect the exhaust system, connectors, hoses, belt lines, and air filter.

- Make sure that electrical connections in the generator are working fine. You’ll need to change the fluids on an annual basis at least to keep the cooling system’s configuration efficient.

- Perform fuel reconditioning and polishing if the filters are clogged and collecting sludge. Exhaust smoke and bad fuel injectors can cause clogged filters for which you’ll need polishing.

Generators are complex machines and apart from minor maintenance tasks, it’s impossible to handle the upkeep on your own.

While you can find the source of fluid leaks or fix the ill-fittings by yourself, for complicated steps, it’s best to leave the job to our professional team that is equipped to handle any generator and transformer related challenges.

At RHK Electrical, we serve both residential and commercial clients in Cypress and adjoining Texas counties. Get in touch with us here.