When it comes to electrical safety, prevention is always better than cure. Unfortunately, some people learn this lesson the hard way. But you don’t have to be one of them.

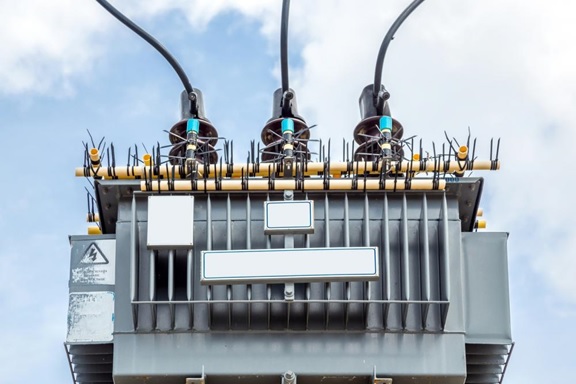

One of the most important components of your home electrical system is the transformer. Several types of maintenance checks can be conducted on an electrical transformer to ensure its upkeep.

READ: How do electricity transformers work?

Here are five essential maintenance tips that you should know:

Tip#1: Prepare a maintenance schedule for the magnetic oil gauge

It’s important to check the oil levels of the magnetic oil gauge of the conservatory and main tank regularly to ensure it’s filled up to optimal levels. Ideally, you should check the oil levels every month to make sure it doesn’t go down below the threshold to prevent damage.

Also, you should hire a professional electrician to carry out an annual examination. They will take a sample from the drain valve and perform tests to check whether the MOG needs to be replaced.

Tip#2: Make sure the transformer is operating within a reasonable load capacity

Electrical transformers that work under a reasonable load capacity last longer, and are less prone to malfunctioning or presenting electrical problems.

Hence, you must regularly check the load capacity of your transformer. Preferably, it should be somewhere between 75 to 90 percent of the rated capacity.

If you see the value exceeding the specified number, it’s important to call your electrician to ensure efficient operations and prevent damage.

Tip#3: Preservation of silica gel

Silica gel plays a significant role in ensuring that electrical transformers are working optimally; you must keep the breathing holes clean to facilitate proper breathing action.

READ: Function of Silica Gel Breather

Also, carefully observe the color of the silica gel. If it shows a tinge of pink color, you should get it replaced.

Tip#4: Test for open circuit faults frequently

Open circuit faults are one of the most common defects that occur in transformers. The most common cause behind these malfunctions is lead wire or internal coil breaks.

The diagnosis of this problem isn’t very straightforward, but you might be able to detect the open circuit faults using a multimeter (multitester).

Regardless, it’s vital to take corrective actions in a timely manner to prevent the issue from intensifying into more significant problems.

Tip#5: Hire professionals to carry out a yearly inspection

Last but not least, you must hire professional electrical to conduct a yearly electrical inspection.

It will help ensure whether air fans, oil pumps, and other components that are pertinent to your electrical transformer are functioning correctly.

Yearly preventative maintenance can save you from the massive headache of electrical breakdowns and costly repairs that follow.

Looking for a reputable electrical service provider to evaluate the condition of your transformer? At RHK Electrical, our certified and highly trained professionals provide top-quality electrical installation, repair, and maintenance services to clients in Cypress, TX.

To find out more, call at +1 832 948 6019 today!